Command entry:

Command entry:Select a Body Object.

Modify panel

Editable Body Object rollout

Click Welding button.

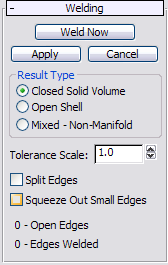

Welding rollout

The Welding rollout lets you specify how to to sew or stitch edges together. Welding is cumulative in that after you weld

the result is kept and used again after you adjust the parameters. In general, start with a Tolerance Scale value of 1.0 (the

default) and increase it.

If you access the Edge sub-object level before welding, you can see the edges that are sewn (white) and the open edges (blue).

Non-manifold edges (edges with more than two faces) are shown in dark orange. For an illustration, see Edge.

Welding mode is active as long as the rollout is open. You can change parameters and weld repeatedly until you achieve the

desired result before exiting the mode. To exit, click Apply or Cancel on the Welding rollout.

Procedure

To use the welding feature:

- Select an object to weld, access the Edge sub-object level on the Modify panel, and activate Wireframe display mode.

- On the Editable Body Object rollout, click the Welding button.

This opens the Welding rollout.

- Choose the desired Result Type option.

- Set the Tolerance Scale value and any options.

- Click the Weld Now button and, at the bottom of the rollout, check the number of open and welded edges.

- If necessary, adjust the Tolerance Scale value and other options.

- Click Apply to save results to the Body Object or Cancel to revert to original Body Object. Either command also closes the

Welding rollout.

Interface

- Weld Now

-

Welds using the current settings and remains in Welding mode.

- Apply

-

Saves the current result and exits Welding mode, closing the Welding rollout.

- Cancel

-

Reverts to the original model and exits Welding mode, closing the Welding rollout.

- Result Type

-

Choose the welding output:

- Forms a closed solid after welding.

- Forms an open shell after welding.

- Choose this option if the model is not very clean and extra work might be needed to get a good result.

- Tolerance Scale

-

Specifies a scaling to be applied to the Body Tolerance to get a Welding Tolerance. A good tight Body Object can be welded

cleanly with a Tolerance Scale value of 1.0. Bodies that are not well connected at the edges might require a higher Body Tolerance

value to weld correctly: 10.0, 100.0, or possibly even 1000.0. Be careful with values above 100, which might remove small

edges.

- Split Edges

-

When on, splits edges at T junctions.

Sometimes a model does not have a 1:1 correspondence in edges between adjacent faces. For example, an object might contain

a T junction where two surfaces join along one edge of a third surface.

- Squeeze Out Small Edges

-

When on, the welding attempts to weld together the two vertices of edges smaller than the welding tolerance, thus deleting

the edges. To prevent the loss of potentially important geometry, avoid using this option with Body Objects that contain very

small pieces when welding with larger tolerance settings.

- # - Open Edges

-

Displays the number of open edges in the Body Object.

- # - Edges Welded

-

Displays the number of edges that were welded the last time you clicked Weld Now.