Create a ball corner surface between

three fillets and a primary surface.

This tool simplifies

the task of creating ball corners.

Given the following conditions:

- Three transitional surfaces (fillets)

intersect at a corner with a primary surface.

- Two boundaries (or curves on surface)

on the primary surface overlap the boundaries of two different transitional

surfaces.

the following steps will

produce a clean result.

Create a ball corner

surface between fillets

- Choose Surfaces > Ball Corner

.

.

- Select the three intersecting transitional

surfaces.

- Press the Go button.

- Select the primary surface.

- Press the Go button.

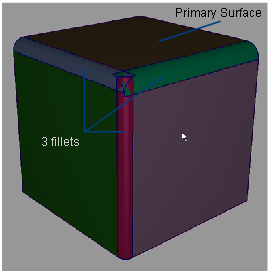

The transitional surfaces

are highlighted in purple, the primary surface is highlighted in

yellow, and small red arrows appear, indicating the intersection points.

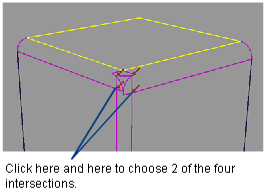

- If more than two intersections are found,

you must click on two of the arrows to specify the intersections

that will correspond to two corners of the ball corner surface,

and then press the Go button.

The input surfaces are

trimmed at their intersections, the ball corner surface is built,

and the option box pops open.

- Adjust the Pivot Curve Length Ratio (to shrink

or expand the top edge of the ball corner).

- Choose a level of Continuity and

turn on Continuity Check.

- Turn on Explicit Control and

use the Explicit Control sliders to adjust the degree and number

of spans (in both U and V direction) on the ball corner until the

desired continuity is achieved. Or just try increasing the Max.

New Spans value.

NoteYou will only see the Max.

New Spans option if Explicit Control is

off, and Continuity is Tangent or Curvature.

Every time the value of an option changes, the

curves on surface that were created on the input surfaces update,

the surfaces are re-trimmed (if needed), and the ball corner surface

is rebuilt (if Build Surface is turned on).

The ball corner surface

is also rebuilt if the input fillet surfaces are modified.

See Troubleshooting trimmed surfaces

.

.