If, after setting up

a Transformer Rig and clicking Go, the surfaces

do not update as expected,

- Check to see if the rig was set up properly.

- check to see if target surfaces are drawn

using dashed lines: that is how the tool indicates there is an error

in the calculations.

- The first setup might not be the best:

try modifying the rig and recalculate to see if the results are

improved.

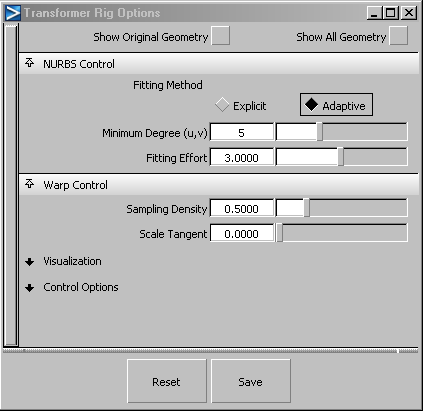

- Try the options in the current selected

Fitting Method.

- increasing the values in the options

tends to give you a more accurate result which takes longer to compute

- Try the other Fitting Method.

Each case is different

— it all depends on the geometry and the intent. As you gain experience

using the tool, you will develop a better feel for which method

works best.

- Draw Correspondence gives visual feedback

as to whether there are conflicts in the rig, as a result of interfering

modifiers and constraints. The visualization is green where there

is no conflict, and graduates from green to yellow to red to show

regions of conflict. This is a good diagnostic tool when the shape

modification behaves wildly.

In the following image, the modifier and the

constraint intersect. Notice that close to the intersection point,

the visualization turns from green to yellow to red, to indicate that

there is a conflict.

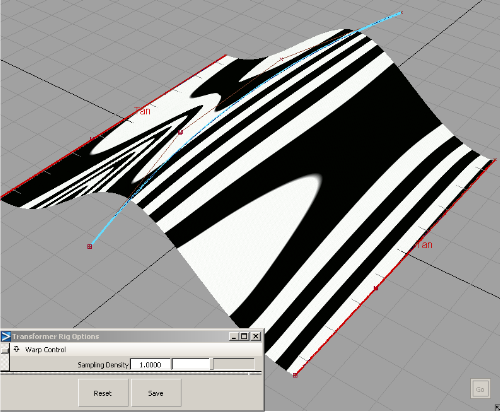

- The Sampling Density field controls quality

and speed. A low value results in faster updates, but may introduce

quality problems. A higher value results in a more faithful shape

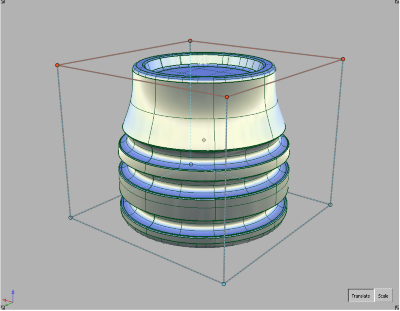

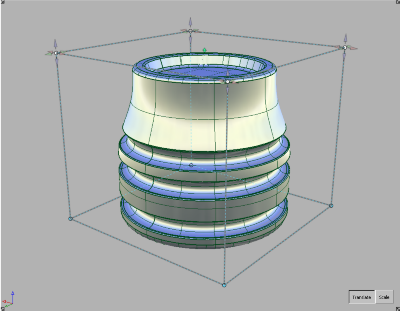

modification, but increases the update time. The following images

show how artifacts are introduced when sampling is too low, and

how they can be avoided with a higher sampling rate.

- Several factors may contribute to undesirable

shape artifacts. They have been discussed above, and may include

inappropriate NURBS fitting, low sampling density, and conflicts

between constraints,modifiers, and clampers. To rule out inappropriate NURBS

fitting, try toggling Mesh Output and seeing whether artifacts are

affected. To rule out sampling density, try a higher sampling density

setting.

- After setting up a Lattice Rig, the rig

may be partially or totally locked.

- If you are modifying trimmed surfaces,

the part of the lattice that intersects with the discarded portions

of the trimmed surfaces is locked. In this case, shrink the trim

surface with the shrinkToTrim plug-in.

- If you are modifying NURBS surfaces that

protrude from the lattice, the outside portions may be modified.

This is due to the global effects of NURBS fitting. If you want to

reduce these effects, increase the number of spans. To eliminate

them entirely, you may have to switch to Mesh Output.

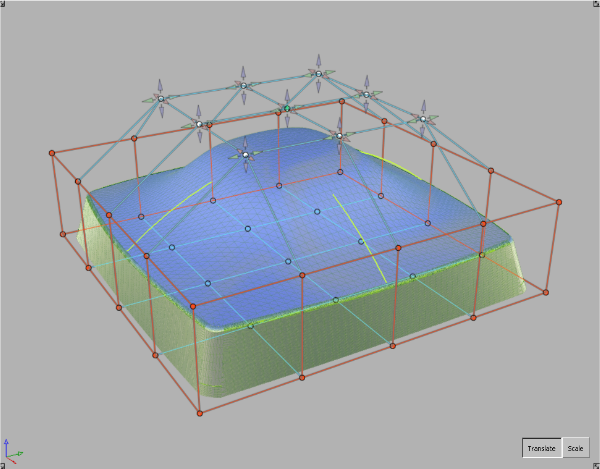

- When the Lattice Rig is applied to this

surface, the two sides of the lattice are locked, with no obvious

reasons.

If you turn on the CVs of the surface, you see

that the surface is a trimmed surface, and the removed parts intersect

with the lattice.

Shrinking the trim will fix this problem.

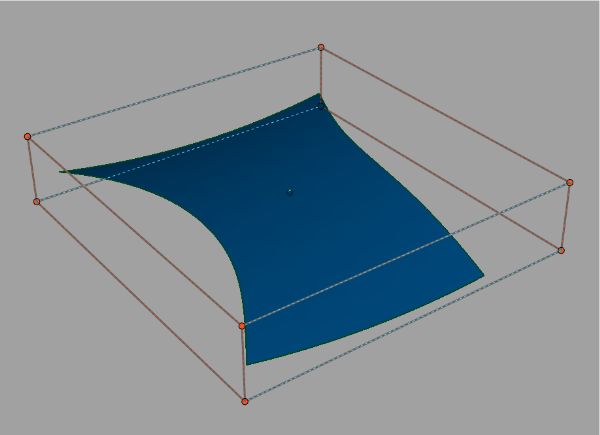

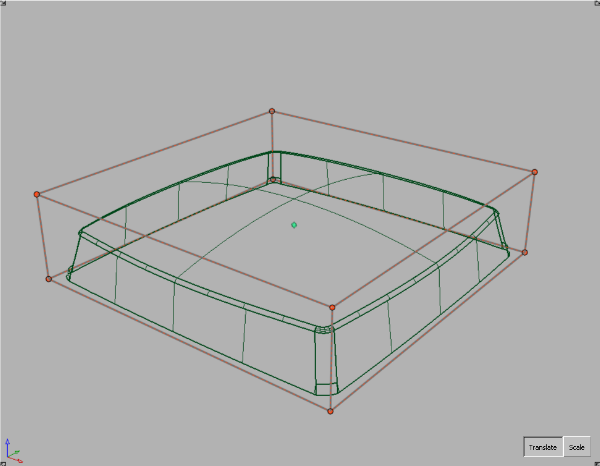

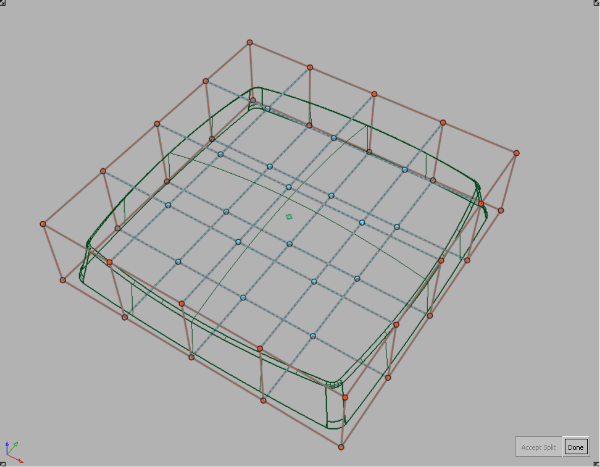

- The Lattice rig may be too close to the

surface. In these cases, move or scale the lattice away from the

target geometry. In this example, the initial lattice is too close

to the top of the target.

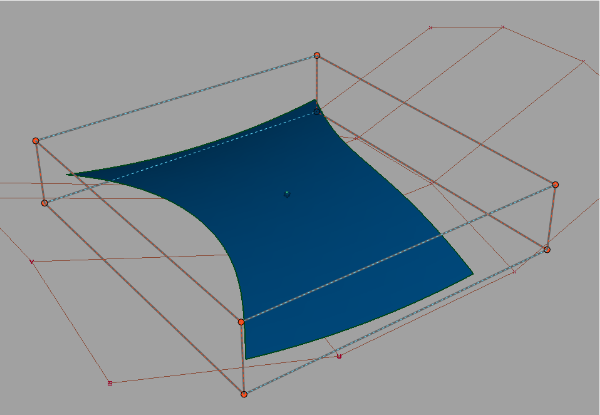

Translating the top of the lattice upwards solves

the problem.

- Refine the lattice using the Split

Edge tool to give it more degrees of freedom.