The Tube Flange tool provides you with an automatic functionality to create a finish on the edges of a surface model. By using one or more of the following: edge, curve-on-surface, boundary edge, or iso-parametric line, the tool creates a tube that touches the selected geometry. The tool also creates a linear extension — a flange — on the tube. This extension can be defined by a sweep angle or a vector plus a draft angle.

Choose either Tangent or Curvature continuous to the base surfaces.

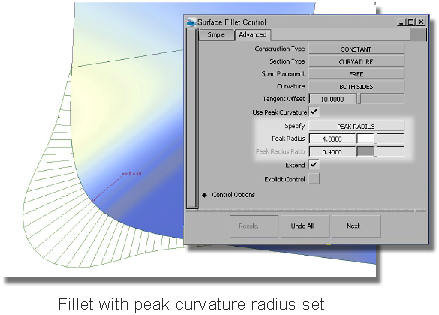

If Curvature is selected, Use Peak Curvature options can be set:

The peak radius parameter is only visible if the fillet/tube radius/tangent offset is not variable. If is visible you can specify either a radius or a ratio.

The ratio is the ratio of the radius/tangent offset to the peak radius, and can be used for either variable or fixed radius fillet.

The following illustration shows the difference peak curvature can make to a fillet.

Defines the radius of the tube. This option is grayed out if Variable is set to Radius and more than one manipulator is used. You must define the radius interactively on the model by dragging the manipulator in that case.

If you choose Single surface, a single tube surface is built. If you choose Multiple surfaces, the tube is split at curve boundaries, which also include surface boundaries, since a curve cannot span more than one surface.

Enables you to put the tube on top of or underneath the surfaces.

This option only appears if Surface Type is set to Multiple surfaces. If it is checked on, each surface will be a Bézier patch.

Bézier patches have a single span, and their maximum degree in the U direction is set through the Explicit Control section. The default is degree 5.

Gives you controls of the surface degree and maximum number of spans in the tube surface.

The degree of the tube surface. Enter a whole number from 2 to 9. This option is only available when Explicit Control is checked.

If Surface Type is set to Multiple surfaces, this value specifies the maximum number of spans for each tube surface. If Surface Type is set to Single surface, it specifies the maximum number of spans for each piece of the original surfaces.

This option is only available when Explicit Control is checked, and Bézier Surfaces is not checked.

Explicit control applies to Tube only: a separate control is provided for Flange.

Set to either Sweep angle or Parting line. Sweep angle defines where along the tube the flange will be tangent to the tube. Parting line uses a vector and draft angle that determines the direction of the flange. If you select Parting line, you must pick a vector, or specify it through the Parting Line Vector Options.

Provides a slider to control the angle. The default is 90 degrees for Sweep, and 0 for Draft angle. Either angle can be variable.

Enables you to flip the direction of the flange. This option is grayed out if at least one of the input curves is an edge, and thus, there’s only one valid orientation of the flange.

Determines whether or not a flange will be built off the edge of the tube. To create a full tube, use a Sweep Angle of 360 degrees. Note that the tube will be trimmed according to the Sweep Angle or Parting Line settings, even if Create Flange is off.

Determines the length of the flange that will be built, if Create Flange is on. Length can be variable.

Gives you controls of the surface degree and maximum number of spans in the flange surface.

This controls the flange only.

The degree of the flange surface. Enter a whole number from 2 to 9. This option is only available when Explicit Control is checked.

The maximum number of spans in the entire flange surface if Surface Type is set to Single surface, or per surface if Surface Type is set to Multiple surfaces. This option is only available when Explicit Control is checked.

These options only apply when Flange Type is set to Parting line.

Select one of these to specify a pull direction along that axis.

Select this option to specify a pull direction normal to the current view. The vector is not drawn in the view windows.

If the current view is changed, click Refresh View Vector to update the vector.

Selecting this option lets you specify the name of an existing vector in the Picked Vector field, or pick the vector in the view. This vector defines the pull direction.

This button only appears if View is selected. Click it to update the vector if the view has been modified.

Click this button to create a vector construction object in the view windows. Unless you do this, the vector direction you specified is used by the tool, but you will not see and be able to re-use the vector.

Note that only one of the three parameters can be variable. For example, it is not possible to create a variable radius tube with a variable length flange.

Gives you the ability to interactively modify the Flange Length, Flange Angle, or Radius.

If this box is checked, selecting a surface curve also selects all other surface curves that are tangent continuous with it.

Choose whether to get visual feedback about continuity (set in the Tube section). Green indicates success; yellow indicates that the continuity condition has not been met.

Choose between updating changes by selecting the Recalc button, or automatically updating changes.

Variable controls for this tool are provided in the modeling window.

Controlling the variable parameter in Tube Flange

The variable parameter (radius, flange angle, or flange length — as specified by Variable in the control window) is controlled using a set of manipulators in the modeling window. Only one of the parameters can be varied: the other two are held constant.

Each manipulator consists of two handles — the rail slider and the value handle — only one of which can be active at a given time. The active handle is shown in light blue. The rail slider, a "ball" sliding along the rail, indicates the position on the rail where the value applies. The value handle, an approximate cross section of the future surface, controls the value of the parameter at this point.

The value of the active handle is shown on the prompt line.

For all of the following

operations, use the  , unless stated otherwise.

, unless stated otherwise.

To activate a handle, click it.

To de-activate the currently active handle and switch back to the picking mode, click anywhere on the screen (without dragging the mouse).

To add a new manipulator, click the desired point on the rail.

To move a manipulator,

drag the slider using the  . Alternatively, activate the

slider and type in the position (in the range from 0 to 1) along

the rail.

. Alternatively, activate the

slider and type in the position (in the range from 0 to 1) along

the rail.

To adjust the parameter value, click and drag the value handle. Once the handle is active, the mouse can be dragged anywhere on the screen. Alternatively, activate the handle and type in the value in current units.

To delete a manipulator, Shift-right click it.

If a single manipulator is used, the parameter is constant, and its value can also be adjusted in the control box. As soon as another manipulator is added, the value in the control box is grayed out.