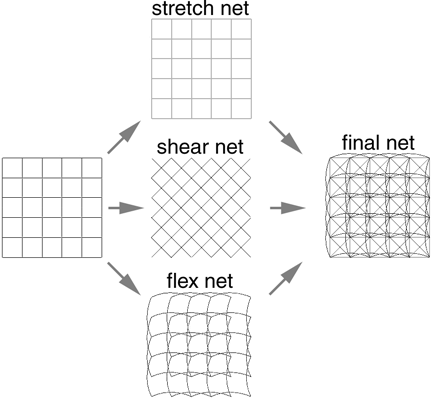

Cloth deformation is controlled by a virtual "spring net." Springs are distributed onto the cloth surface and connect the vertices of the model according to a specific rule.

There are three different types of springs that constitute the spring net, each controlling a different kind of deformation:

Stretch springs, which connect adjacent vertices of polygons or quads. They correspond to the visible edges of the wireframe model.

Shear springs, which connect non-adjacent vertices of the same polygon or quad.

Bend (flex) springs, which are the same as Stretch, but connect every other vertex, skipping the adjacent ones.

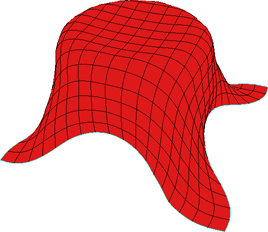

This illustration shows how cloth is applied to NURBS surface objects:

Shear, Bend, and Stretch Resistance (Stiffness)

The elastic constant values associated with these springs are the Stiffness parameters found on the Cloth Property Editor. They define how soft or rigid a fabric is, such as the difference between silk and leather.

To help reduce that stretchy, "rubbery" look when a cloth drapes over an obstacle, use high values for all the Stiffness parameters. Low values (no resistance) allow the cloth to deform without resistance.

You can set the cloth's Initial Tension %, which gives an initial tension to the cloth by stretching or compressing the springs used to simulate the fabric.

And setting a Stretch Limit can help stabilize a cloth simulation.

|

|

| Shear Resistance value of 1 on Silk cloth preset. |

Shear Resistance value of 100 on Silk cloth preset. |